2.3 Micro-Step

The Micro-Step mode divides the full step angle into smaller steps, providing even smoother operation and higher precision. The number of micro-steps per full step can vary. But in this demo it is implemented with 32 micro-steps per full step. Even though this mode requires the most complex control algorithms, the current consumption is lower than in full step and Half-Step modes, providing the highest accuracy, the lowest vibration, and less noise. Micro-Step mode is often used in applications where accuracy and smoothness of operation are paramount, such as in CNC machines.

The TCE peripheral has two primary functions. It generates the PWM signal and modulates the signal amplitude. The function generates the PWM signal according to the LUT array of 32 positions, scaled form 0 to 99%.

In the current implementation, 32 micro-steps are used for every 90° of the wave, equivalent to 32 micro-steps per full step.

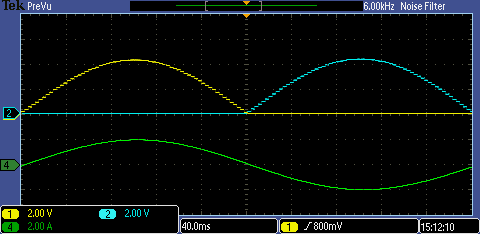

The colors used in the figure are yellow and blue, symbolizing the voltages at the two ends of coil A. Green symbolizes the current through coil A. Applying low pass filtering from the oscilloscope will remove the PWM artifacts and make the short-time average values visible on all three traces.