1.4 Overview – Stepper Run Modes

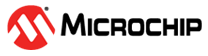

Full-Step

In Full-Step mode, the motor rotates complete mechanical steps at once - for a standard 200 full-steps/revolution stepper motor, this would be 1.8° for a single step. The motor's two coils are powered sequentially in four full steps. The sequence determines the stepper motor's direction of rotation. Full-Step mode is simple to control, but can cause vibration and noise due to the large step angle. Another drawback of using this mode is that the stepper motor's current consumption is at the highest level, having the lowest efficiency. This mode is often used in applications where the drive algorithm simplicity is more important than the smoothness of operation or precision.

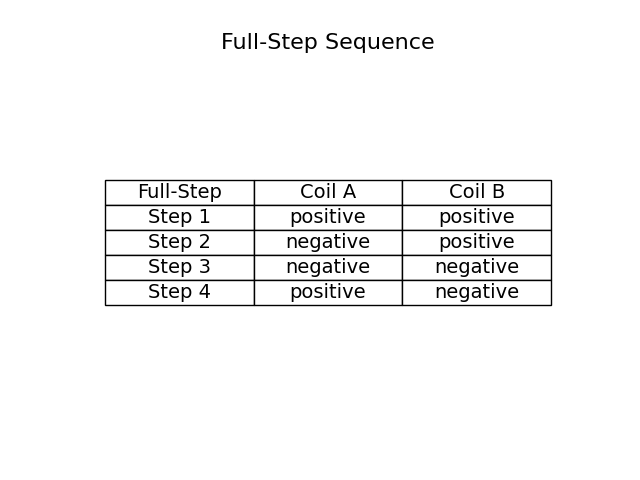

Half-Step

In Half-Step mode, four extra steps are inserted between the four initial full steps, making the stepper motor rotate by half its full-step angle, effectively doubling the number of mechanical steps per revolution - for a standard 200 full-steps/revolution stepper motor, this would be 0.9° for a complete step, resulting in a smoother operation and less vibration than the Full-Step mode. The benefits of having a balance between simplicity, efficiency, smoothness of operation, and lower current consumption outweigh the increased complexity of the control algorithm needed for this mode. It also provides double resolution of the Full-Step mode.

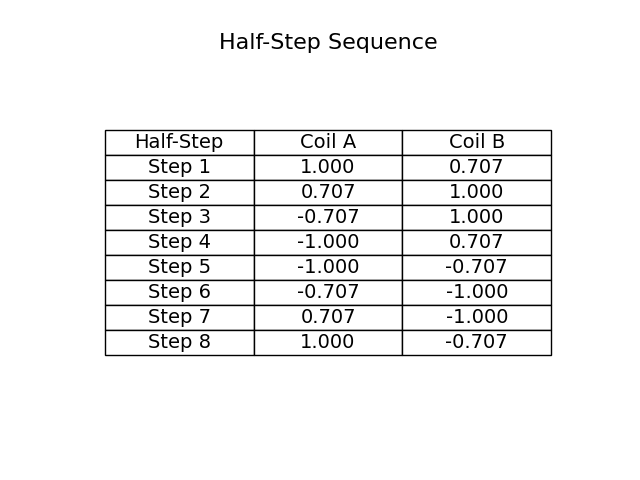

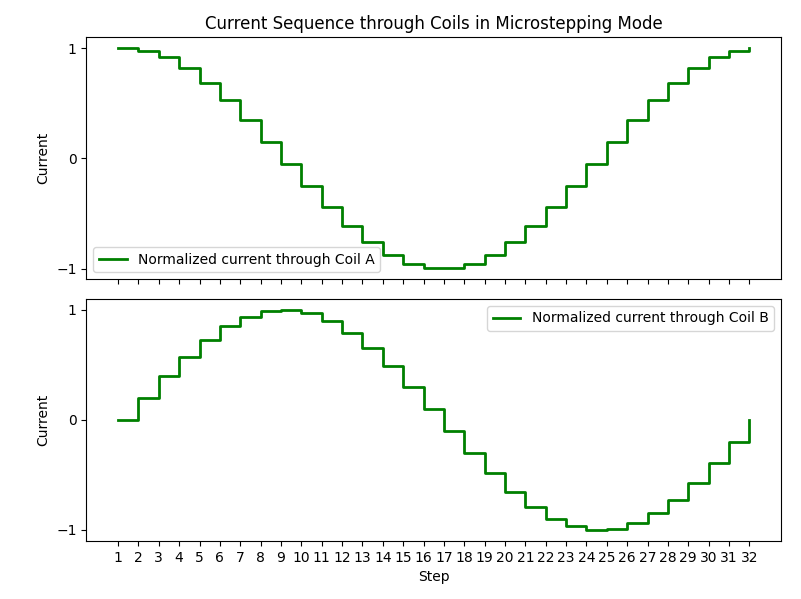

The green represents the current through coils A and B.

Micro-Step

The Micro-step mode divides the full-step angle into smaller steps, providing even smoother operation and higher precision. The number of micro-steps per full-step can vary, but the typical values are 8, 16, 32, or even 256 micro steps per full-step. Even though this mode requires the most complex control algorithms, the current consumption is lower than in Full-Step and Half-Step modes, providing the highest precision, the lowest vibration, and less noise. Micro-Step mode is often used in applications where accuracy and smoothness of operation are paramount, such as in CNC machines.

In the current implementation, 32 micro-steps are used for every 90° of the wave, equivalent to 32 micro-steps per full step.

Green represents the current through coils A and B.