1.2 BLDC Block Commutation using Hall Sensor

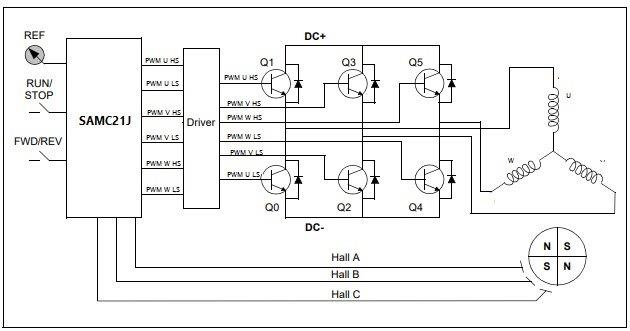

Brushless Direct Current electric motor, or BLDC motors for short, are electronically commutated motors powered by a DC electric source via an external motor controller. This document serves as a guidance to build, configure and run Block Commutation algorithm for BLDC motors on Microchip’s 32-bit PIC32CM MC microcontroller devices.

Description

Brushless Direct Current (BLDC ) motor is controlled using Hall signal based commutation. Motor start/stop operation is controlled by the switch and motor speed can be changed by the on-board potentiometer. Waveforms and variables can be monitored runtime using X2CScope.

Key features enabled in this project are:

- BLDC Commutation

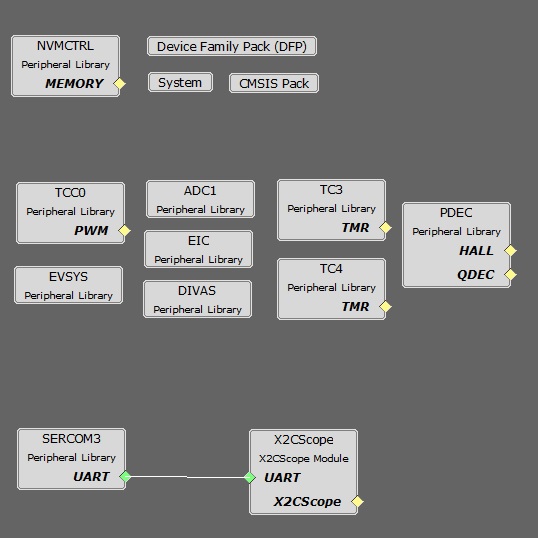

MCC Project Configurations

- ADC0-ADC1 Peripheral:

- ADC0 and ADC1 are setup to operate in Host - Client mode with ADC0 acting as a Host.

- Both ADCs convert single ended inputs. DC link current is sampled and converted by ADC0 which can be used for current control. Potentiometer is sampled and converted by ADC1.

- Both ADCs are hardware triggered simultaneously by an event generated from TCC0 at the end of each PWM cycle.

- Conversion Ready interrupt is generated by ADC0. Since both ADCs are triggered simultaneously and have same resolution and sampling time, both ADCs complete conversion at the same time.

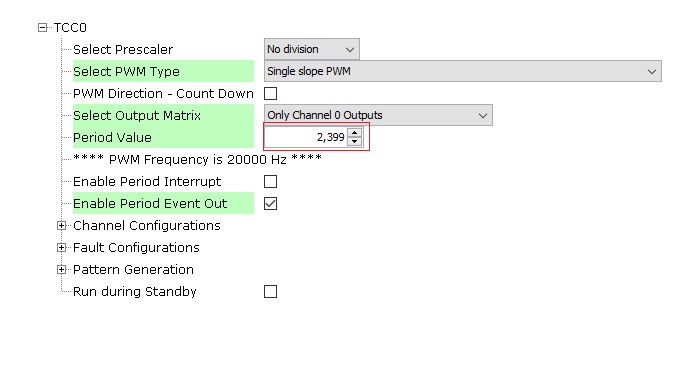

- TCC0 Peripheral:

- Configured to generate 3 pairs of single PWM signals at frequency of 20 kHz in Edge Aligned Mode

- Event output is enabled which is generated for counter overflow

- Non-recoverable Fault is enabled on EV0. When an event is detected on EV0, all PWM channels are held low

- TC3-TC4 Peripheral:

- TC3 peripheral is used as a timer to measure the time elapsed between two consecutive hall edges

- TC4 peripheral is used as an internal 1 mS timer counter

PDEC Peripheral:

- PDEC is used in Hall mode to detect the hall pattern change.

- PDEC VLC interrupt is generated when hall pattern changes.

- EIC:

- External Interrupt Controller detects hardware over-current fault input and generates a non-recoverable fault event for TCC0, thereby shutting down the PWM in the event of an over-current fault

- External Interrupt control also detects hall sensor edges allowing the software to update the commutation pattern

- EVSYS:

- Event System acts as a traffic cop between event generator and event users

- Event generated by the TCC0 when the counter overflows, is used by the ADC0 as a hardware trigger source via Event System

- Event generated by the EIC upon over-current fault, is used by the TCC0 as a non-recoverable fault event via Event System

- SERCOM3 Peripheral:

- SERCOM3 is configured in USART mode and is set to operate at 115200 bps.

- This USART channel is used by the X2CScope plugin to plot or watch global variables in run-time. Refer to X2C Scope Plugin section for more details on how to install and use the X2CScope.

Control Algorithm

Brushless Direct Current electric motors, or BLDC motors for short, are electronically commutated motors powered by a DC electric source via an external motor controller. The electronic commutation to rotate the motor is achieved by a three phase inverter. The commutation technique are broadly classified as block Commutation and Sinusoidal commutation. The block commutation has reduced system complexity as compared to the sinusoidal commutation. Hence, the block commutation technique is quite popular for the low cost applications where control precision, reduced efficiency, and higher acoustic noise are permitted.

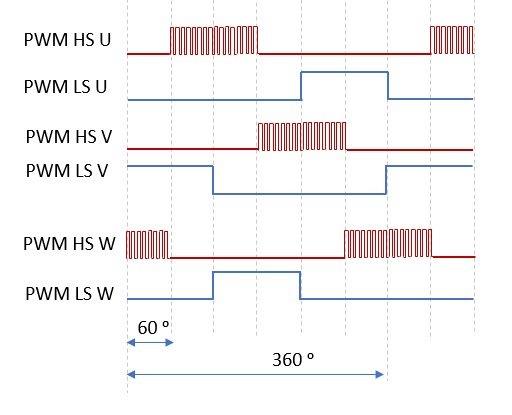

The BLDC motor control using block commutation is done as follows:

- Read the hall sensor input pattern from three 120 degree spatially oriented hall sensor.

- Use the hall sensor pattern to determine the three phase inverter commutation pattern.

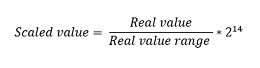

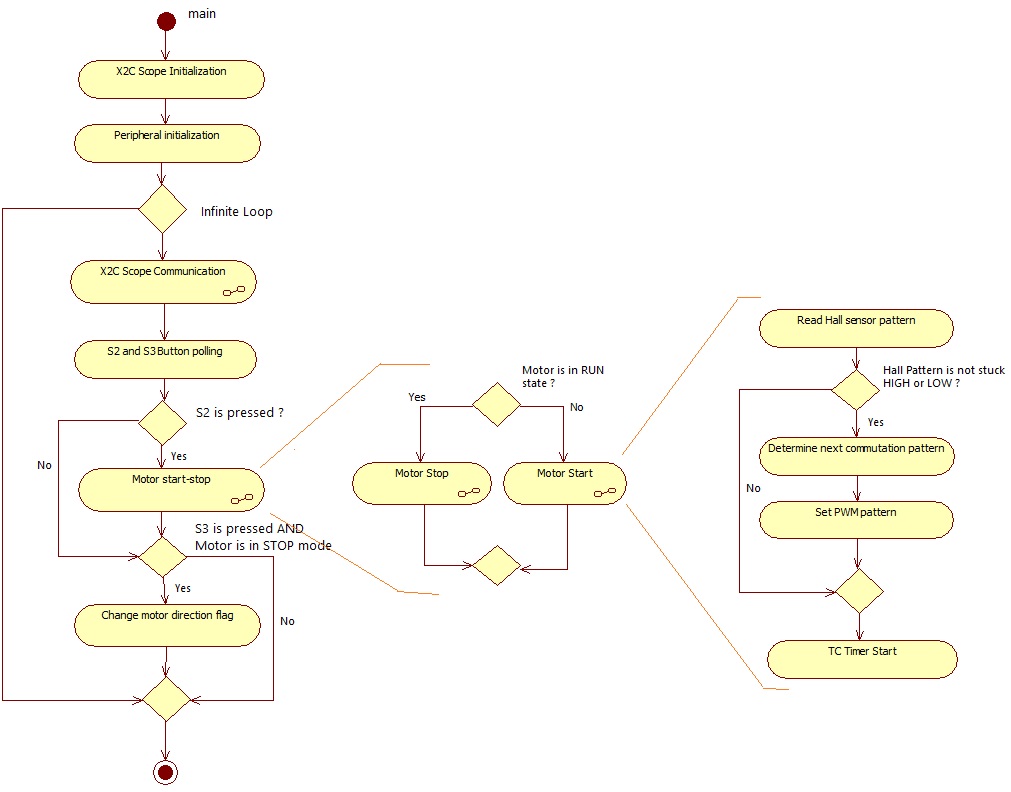

Software Design

This section describes the software design of BLDC block commutation application. The first part of this section, numerical scaling for fixed-point implementation is briefly described. The later section, the software implementation of the example project is described.

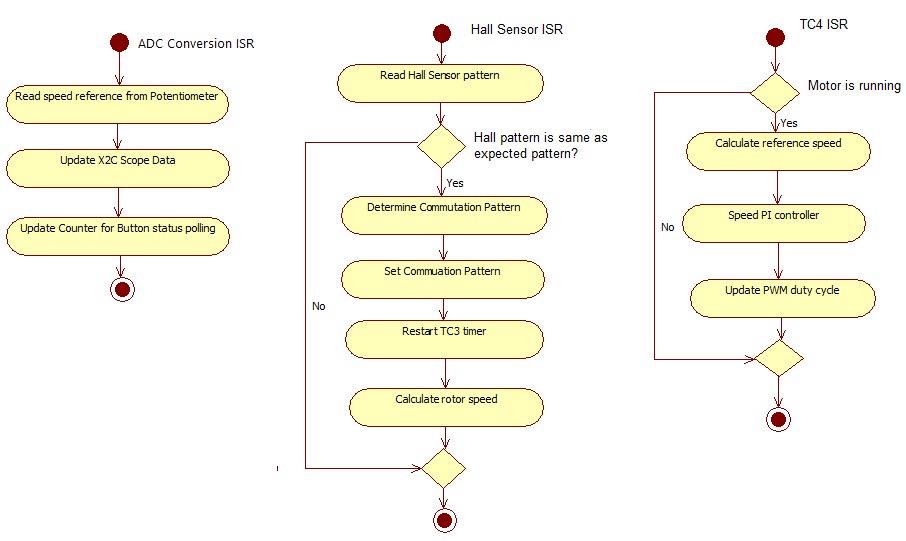

Scaling

The real value range of voltage, current and speed is chosen as independent base quantities for deriving the range of other physical quantities. The independent base quantities are determined by considering the electrical constraints of the MCLV2 development board and the motor used.

Software Implementation

Software Configuration

SETTING MOTOR CONTROL PWM FREQUENCY AND DEAD-TIME:

| Macro | Description |

|---|---|

| PWM_HPER_TICKS | PWM Timer period value = “Period value” defined in MCC + 1 |

| DEAD_TICKS | Dead-time defined in terms of PWM timer ticks = “Dead time value” defined in MCC |

SETTING MOTOR SPECIFIC PARAMETERS:

| Macro | Description | Unit |

|---|---|---|

| MAX_MOTOR_POLE_PAIRS | Number of Pole Pairs | - |

| MAX_MOTOR_SPEED | Rated speed of the motor | RPM |

SETTING HALL PATTERN AND COMMUTATION PATTERN:

| HA | HB | HC | Pattern | Phase U | Phase V | Phase W |

|---|---|---|---|---|---|---|

| 0 | 0 | 1 | V+W- | 0 | H | L |

| 1 | 0 | 1 | U-V+ | L | H | 0 |

| 1 | 0 | 0 | U-W+ | L | 0 | H |

| 1 | 1 | 0 | V-W+ | 0 | L | H |

| 0 | 1 | 0 | U+V- | H | L | 0 |

| 0 | 1 | 1 | U+W- | H | 0 | L |

Hall pattern and commutation patterns are defined in the mc_app.c file. HALL_ARRAY[16] array contains the hall pattern for both the directions - first 8 entries are for clockwise direction and next 8 entries are for anti-clockwise direction.

COMMUTATION_ARRAY[16] array contains commutation pattern corresponding to the hall pattern - first 8 entries are for clockwise direction and next 8 entries are for anti-clockwise direction.

e.g The entry in the commutation array for V+W- is 0x4075. This is given in terms of the pattern enable register TCC_PATT.

Pattern value configuration for V+W- is 0x40. This means low side switch of Phase W is continuously ON.

| X | W- | V- | U- | X | W+ | V+ | U+ |

|---|---|---|---|---|---|---|---|

| 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 |

| X | W- | V- | U- | X | W+ | V+ | U+ |

|---|---|---|---|---|---|---|---|

| 0 | 1 | 1 | 1 | 0 | 1 | 0 | 1 |

Development Kits

MCLV2 with PIC32CM MC Family Motor Control PIM

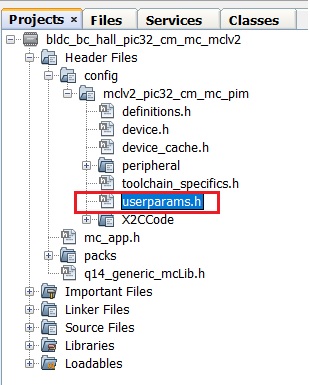

DOWNLOADING AND BUILDING THE APPLICATION

To clone or download this application from Github, go to the main page of this repository and then click Clone button to clone this repository or download as zip file. This content can also be downloaded using content manager by following these instructions.

Path of the application within the repository is apps/bldc_bc_hall_pic32cm_mc.

To build the application, refer to the following table and open the project using its IDE.

| Project Name | Description | Demo User Guide |

|---|---|---|

| mclv2_pic32cm_mc_pim.X | MPLABX project for MCLV2 board with PIC32CM MC PIM | MCLV2 with PIC32CM MC PIM |