2.16 Debugging 3: I/O View Memory View and Watch

This section covers more advanced debugging topics with Microchip Studio as both video (linked below) and hands-on document. The main topics are using I/O View to work with Configuration Change Protected (CCP) registers, Memory View to validate EEPROM writes, and the Watch window to cast pointers as an array.

I/O View

The I/O view provides a graphical view of the I/O memory map of the device associated with the

active project. This debug tool will display the actual register content when

debugging, allowing verification of peripheral configurations. It can also be used

to modify the content of a register without having to recompile.

Todo: Use I/O view

to:

- Get an overview of the device memory map

- Check current peripheral configurations

- Modify peripheral configurations

- Validate configuration changes

- Remove all breakpoints and start a new debug session.

- Break code execution by

pressing the Break All button

.

. - Open the I/O view from the top menu bar by going to Debug → Windows → I/O.

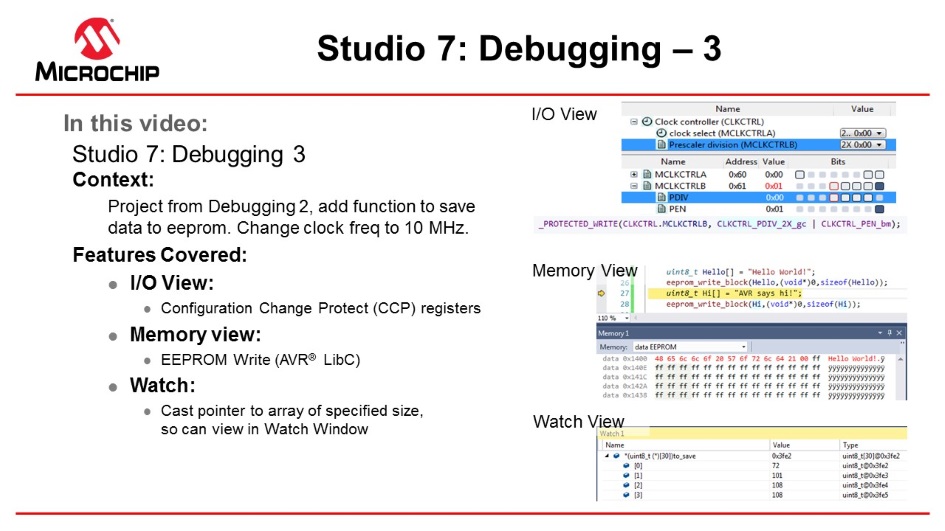

- Scroll through the list of

peripherals and select I/O Ports (PORTB). Find the OUT

register and click on Bit 4 in the Bits column, so the

corresponding square changes color, as depicted in Figure 2-57. Observe that clicking Bit 4 in

the PORTB.OUT register toggles the output level on GPIO pin PB4, which

controls the LED on the ATtiny817 Xplained Pro.

Figure 2-57. Manipulate Bit Value in Register Using I/O View  Info: The I/O view is refreshed after modifying any register, and all detected changes are highlighted in red.Tip: Modify multiple bits simultaneously by double clicking the value field and typing in the desired value to be assigned to the register.

Info: The I/O view is refreshed after modifying any register, and all detected changes are highlighted in red.Tip: Modify multiple bits simultaneously by double clicking the value field and typing in the desired value to be assigned to the register. - Expand the Clock controller

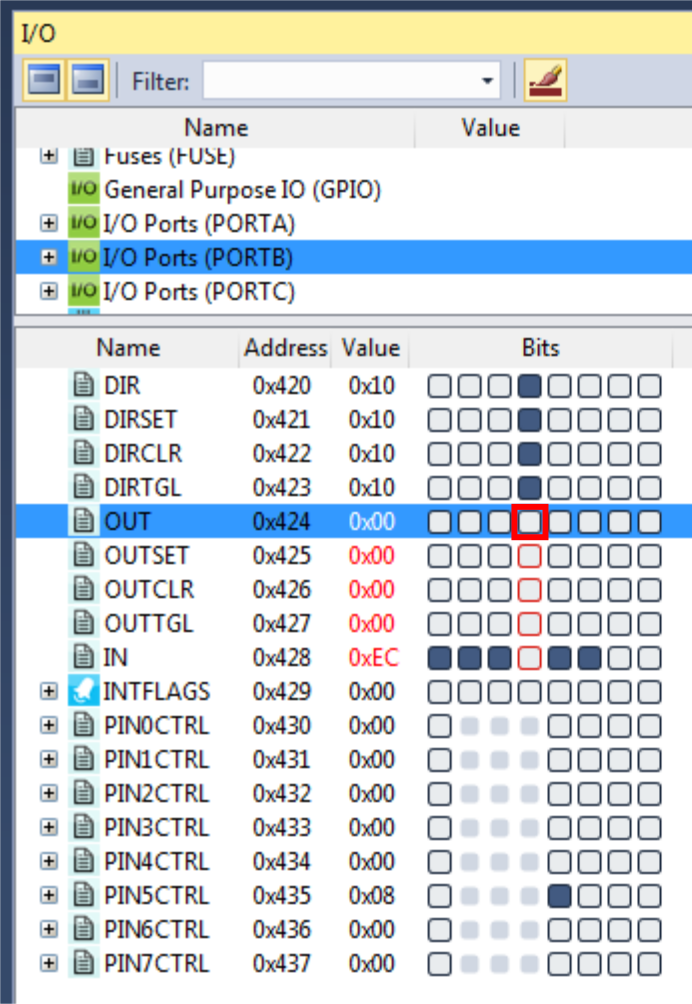

(CLKCTRL) in the I/O view, and answer the following questions:

- What is the currently selected clock source (Clock select)?

- What is the configured prescaler value (Prescaler division)?

- Is the main clock prescaler enabled (MCLKCTRLB.PEN)?

Result: Configure the Clock controller with the ATtiny817 default clock settings; the main clock runs from the internal RC oscillator with prescaler enabled and a division factor of six.Info: The default clock configuration ensures that the device will execute code reliably over the entire supported operating voltage range, 1.8V to 5.5V. The Xplained Pro kit powers the ATtiny817 at 3.3V. According to the 'General Operating Ratings' section in the device data sheet, device runs safely at 10 MHz with a 3.3V supply. - The code will now be changed

to run the ATtiny817 at 10 MHz. Modify the start of

main() as

below:

int main(void) { /* * Set the Main clock division factor to 2X, * and keep the Main clock prescaler enabled. */ CLKCTRL.MCLKCTRLB = CLKCTRL_PDIV_2X_gc | CLKCTRL_PEN_bm; - Start a new debug session to recompile the project and program the device.

- Halt code execution by

clicking

. Examine the clock settings in I/O view,

depicted in Figure 2-58.

. Examine the clock settings in I/O view,

depicted in Figure 2-58.Figure 2-58. Clock Settings in I/O View Remain Unchanged  Result: There is a problem! The prescaler remains unchanged.

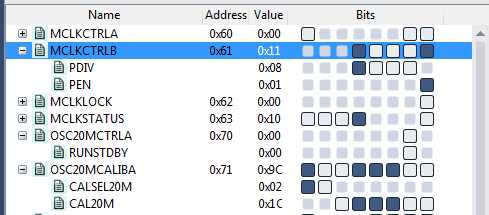

Result: There is a problem! The prescaler remains unchanged. - Select the MCLKCTRLB

register in the I/O view, as indicated in Figure 2-59.

Figure 2-59. Select MCLKCTRLB in I/O View

- Push F1 on the keyboard to

bring up a web-based register description.Info: Internet access is required to use the web-based register description. Refer to an offline version of the ATtiny817 data sheet if internet access is not available.

- Find out if any access

restrictions apply to the MCLKCTRLB register.Result: The Configuration Change Protection (CCP) mechanism protects the register. Critical registers are configuration change protected to prevent unintended changes. As described in the data sheet, these registers can be modified only when following the correct unlock sequence.

- Replace the line of code,

which was just added, with the

following:

_PROTECTED_WRITE(CLKCTRL.MCLKCTRLB, CLKCTRL_PDIV_2X_gc | CLKCTRL_PEN_bm);Info: _PROTECTED_WRITE() is an assembly macro that ensures meeting timing requirements for unlocking protected registers. It is recommended to use this macro when modifying protected registers.Tip: Right click the macro name in the code and select Goto Implementation to navigate to the macro implementation. This is also possible by placing the cursor at the macro name in the code and pressing Alt+G on the keyboard. Use the same process for variable declarations and function implementations. - Stop the previous debug session and launch a new session to program the device with the changes.

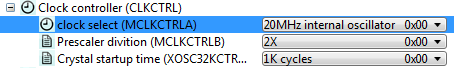

- Break code execution and use

the I/O view to verify that the prescaler is now successfully set to 2X, as

indicated in Figure 2-60.

Figure 2-60. Clock Settings in I/O View Changed Successfully

Tip: The Processor

Status window is the register view tool for the AVR Core. Open this tool from

the top menu bar by going to Debug → Windows → Processor Status. This

window will provide a detailed view of the status of the internal AVR Core

registers. Use this view to check if global interrupts are enabled; look for the

I-bit in the status register.

Result: The

capabilities of the I/O view have been used to find and fix a bug in the

project.

Memory View

ToDo: Write two

strings to the beginning of the ATtiny817 EEPROM and use the Memory view to

verify the EEPROM contents.

- Add #include <avr/eeprom.h> after the #include <avr/io.h> line.

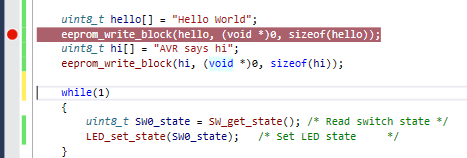

- Add the following code before the while(1) loop in main():

uint8_t hello[] = "Hello World"; eeprom_write_block(hello, (void *)0, sizeof(hello)); uint8_t hi[] = "AVR says hi"; eeprom_write_block(hi, (void *)0, sizeof(hi)); - Place a breakpoint next to the first call to

eeprom_write_block() as in Figure 2-61.

Figure 2-61. Breakpoint to Halt for Checking EEPROM

- Start a new debug session to program the device with the updated code.

- After the breakpoint is hit, open the memory window from the top menu bar by going to Debug → Windows → Memory → Memory 1. Look at the current content of the EEPROM.

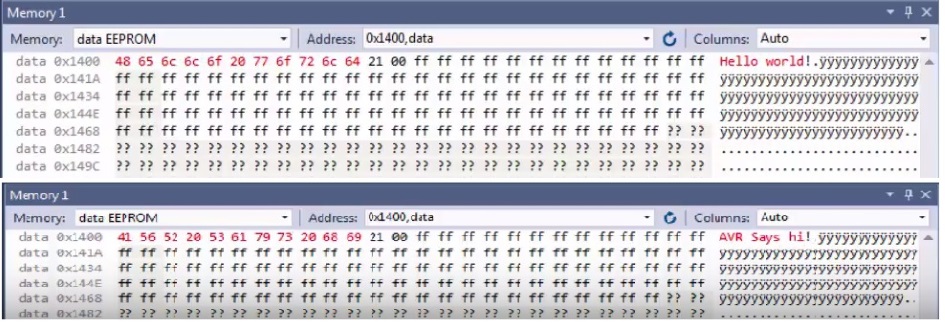

- Push F10 on the keyboard to step over the eeprom_write_block() call and verify the EEPROM write.

- Allow the ATtiny817 to execute the next

EEPROM write before verifying the write using the Memory view. The view

should appear as in Figure 2-62 at each

interval, respectively.

Figure 2-62. Memory View Updating After EEPROM Writes  Tip: The Memory view tool can also be used to investigate the contents of other AVR memory sections, including the program memory. This can be useful when debugging bootloaders.

Tip: The Memory view tool can also be used to investigate the contents of other AVR memory sections, including the program memory. This can be useful when debugging bootloaders.

Result: The content of

the EEPROM is updated after each call to

eeprom_write_block(). The updated content is highlighted in

red, and the ASCII interpretation of the EEPROM content matches the written

strings. Therefore, the contents of EEPROM after writing to it have been

verified using the Memory view.

Watch Window

Watch Window is covered in more detail in section Debugging 2: Conditional- and Action-Breakpoints . However, the note on how to cast pointers as an array in the Watch window is repeated here.

Info: A variable can

also be added to the Watch window by clicking on an empty field name and typing

the variable name. This way, it is even possible to cast a variable to a

different data type for better readability in the Watch window, which is

especially useful if it is required to look at an array passed to a function as

a pointer.

For example, if an array is passed to a function, it will be passed

to the function as a pointer, which makes it impossible for Microchip Studio

to know the length of the array. If the array length is known and needs

investigation in the Watch window, the pointer can be cast to an array using

the following

cast:

*(uint8_t (*)[<n>])<name_of_array_pointer>Test this on the SW0_edge_count variable

by entering the following in an empty name field in the Watch

window:

*(uint8_t (*)[5])&SW0_edge_countResult: Microchip

Studio has now been used to inspect and modify the contents of variables in the

code.

Code Used for Debugging 3

#include <avr/io.h> #include <avr/eeprom.h> void LED_on(void); void LED_off(void); void LED_set_state(uint8_t state); uint8_t SW_get_state(void); uint8_t SW_get_state_logic(void); int main(void) { PORTB.DIRSET = PIN4_bm; /* Configure LED Pin as output */ PORTB.PIN5CTRL = PORT_PULLUPEN_bm; /* Enable pull-up for SW0 pin */ _PROTECTED_WRITE(CLKCTRL.MCLKCTRLB, CLKCTRL_PDIV_2X_gc | CLKCTRL_PEN_bm); uint8_t Hello[] = "Hello World!"; save(Hello,sizeof(Hello)); uint8_t Hi[] = "AVR says hi!"; save(Hi,sizeof(Hi)); while(1) { uint8_t SW0_state = SW_get_state_logic(); /* Read switch state */ LED_set_state(SW0_state); /* Set LED state */ } } void save(const uint8_t* to_save, uint8_t size) { eeprom_write_block(to_save,(void*)0,size); } uint8_t SW_get_state() { return !(PORTB.IN & PIN5_bm); } uint8_t SW_get_state_logic(void) { static uint8_t SW0_prv_state = 0; static uint8_t SW0_edge_count = 0; uint8_t SW0_cur_state = !(PORTB.IN & PIN5_bm); /* Read the current SW0 state */ if (SW0_cur_state != SW0_prv_state) /* Check for edges */ { SW0_edge_count++; } SW0_prv_state = SW0_cur_state; /* Keep track of previous state */ /* * Report the switch as pushed when it is pushed or the edge counter is a * multiple of 3 */ return SW0_cur_state || !(SW0_edge_count % 3); } void LED_off(void) { PORTB.OUTSET = PIN4_bm; /* Turn LED off */ } void LED_on(void) { PORTB.OUTCLR = PIN4_bm; /* Turn LED on */ } void LED_set_state(uint8_t state) { if (state) { LED_on(); } else { LED_off(); } }